It all started with that I lost a piece of string on a Rokkaku of mine. You know, the string that ties the spine and the cross spreader to each other. And it was waiting to happen. Normally I would have sewed that string to the sail, but for some unknown reason, I hadn’t done that.

Then I got this idea. Why not using a cross fitting instead, a cross fitting connecting the spine and the cross spar!

Initially, I was thinking of using a 90° fitting and drill a hole through it, but as my mind started to drift, I suddenly came up with another solution.

And like said in the excerpt, all you need is….

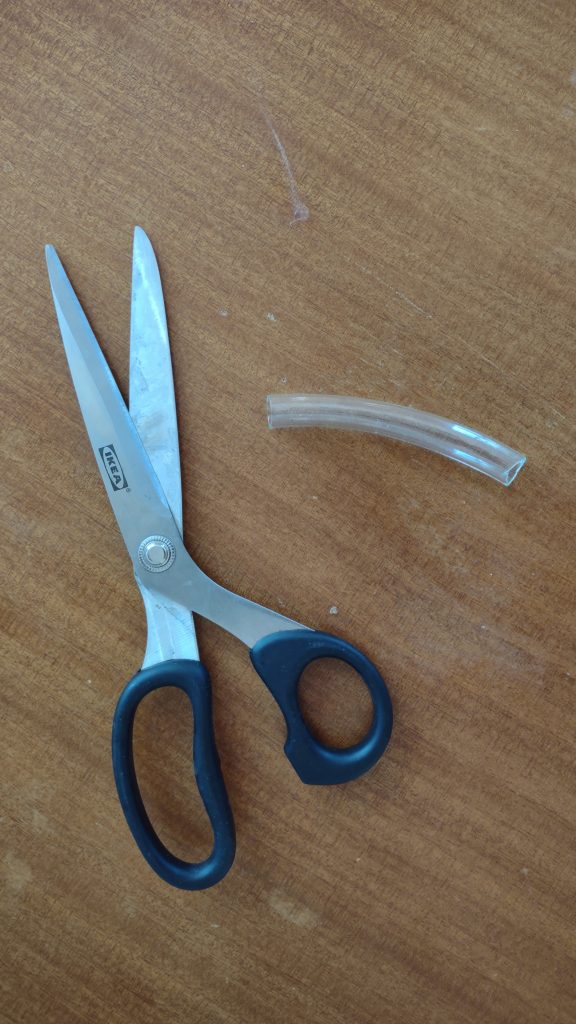

- A piece of plastic tubing

- A pair of scissors

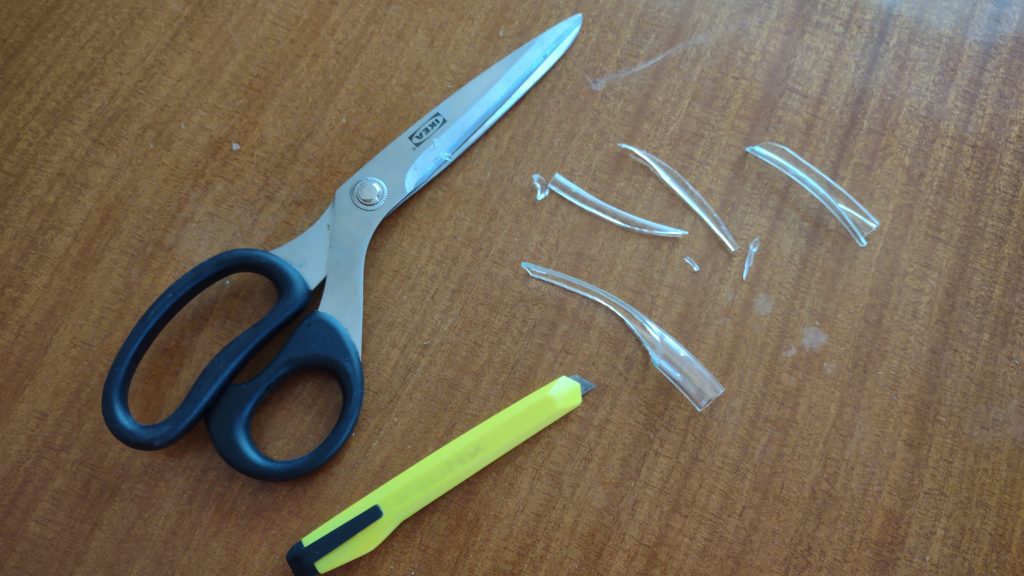

- A sharp knife

- A hole punch tool

Ok, let’s get started!

First, cut of a piece of the plastic tubing making it 10cm give or take.

Now you use the knife and/or the scissors and start trimming the 10cm plastic tube.

…and when done, the piece of tube should look something like this…

Now the fiddling starts! Bend the trimmed end and insert it into the complete tubing like in the photo below.

Now insert a spar into the ‘loop’ created by the trimmed end of the tubing. A picture says more than a thousand words, so check out the photo below for the details!

Now is time for picking up the hole punch tool and, yes, you’re right, punch a hole through the tubing. Make sure to punch through both the tube and the inserted trimmed piece. And the hole should be at 90° at the inserted spar so the whole thing ends up as a cross fitting.

…and when completed, the fitting should look like this.

Now it’s time to insert the cross spar. In my example, I use a 6mm carbon fibre rod and it’s s pretty snug fit. Make sure to push the rod through all three holes in the fitting.

And with both spars inserted, this is starting to look like a proper cross fitting!

Cut off any excess tubing….

…and your DIY cross fitting is good to go!

I’ve already equipped a couple of my rokkakus with this type of cross fittings … and they work like a charm!

Perhaps a little less durable than production made ones, but the will definitely hold up a few hours if you pay attention to the trimming of the tubing so you’ll avoid weak points.

I hope you’ve liked this little how-to post and feel free to drop me your comments in the comments field below!

Just Fly!

2 responses

Clever folding/use of PVC(?) tubing!!! Looks tidy and inviting would the need arise. My only experience with something similar to this type of repair was a holiday “emergency” (well I had only brought a few kites for a two week stay…) Prism Elixir repair. A lower spreader end nock was broken after landing on the stone beach. After getting caught between two stones in the same abrasive beach, about 2cm of the lower leading edge carbon fibre tip also broke. The repair?: PVC tubing and jalousie string bought at the hardware shop at the small Devon coastal town (even got my hole punch pliers there).

This DIY fitting made me think/speculate (which is way quicker than actually doing…). Can PVC be molten and plastically shaped into the desired shape? Well from Wikipedia PVC gets soft (glass transition temperature) around 82degC and melts somewhere in the range 100 – 260 degC. The search “DIY mould melt PVC” didn’t give much unless one would get hold of some injection moulding gear. But still, would it be possible to cross two circular metal bars using your PVC fitting and wrap aluminium tape around it as some kind of mould? Then keep it over a hotplate for background heating and apply extra heat with a hot gun for the final heating?

Naah to complex perhaps… Instead of melting the PVC tube one could use hot melt glue/adhesive for plastics (Polyamides and polyesters: https://en.wikipedia.org/wiki/Hot-melt_adhesive#Materials_used , Yellow. For most plastics https://www.biltema.se/en-se/construction/chemicals/glue-guns/melt-adhesive-for-glue-gun-2000017179 ) to glue your PVC fitting together?

What about making a mould of silicone from an existing fitting instead of any aluminium tape? It should be rather heat resistant ( https://en.wikipedia.org/wiki/Silicone_rubber , https://www.biltema.se/en-se/construction/chemicals/silicone/silicone-high-temperature-2000017141 ). Instead of PVC tubing perhaps using the polyester/polyamide heat glue directly in the mould to form the fitting itself?

…Clever folding/use of PVC(?) tubing!!! Looks tidy and inviting would the need arise. …

Thank you! 🙂

Yes, I think this is a pretty useful solution for making a cross fitting … for different use.

As a quick fix if you happen to break a centre tee on the field, for various build projects and … more.

Durability…? Well, if you pay attention to the trimming and the hole-punching, I guess it could last quite a few hours. But of course, it’s not as durable as a machine-made one. But who cares as long as you can keep on flying?! 😉

I guess you can heat a piece of metal and melt the hole instead of using that hole punch tool. Who knows, the melted edge of the hole might add durability. … or not 😉

…and if you give the melting process a go, please keep us posted!?